Since 1990, the REYCO WaterVac® has been a staple in the vegetable and fresh-cut industries, solving clumping issues and even pre-cooling in some cases. It can extend freezer defrost cycles by up to 50%, significantly reducing energy costs and increasing uptime. For example, processors needing an eight-hour defrost can often extend this to twelve hours.

With the rise of fresh-cut fruit, vegetables, and packaged salads, the WaterVac® has found new applications. It helps packagers control moisture before packaging and allows processors to reduce product temperatures after blanching, adding an evaporative cooling effect.

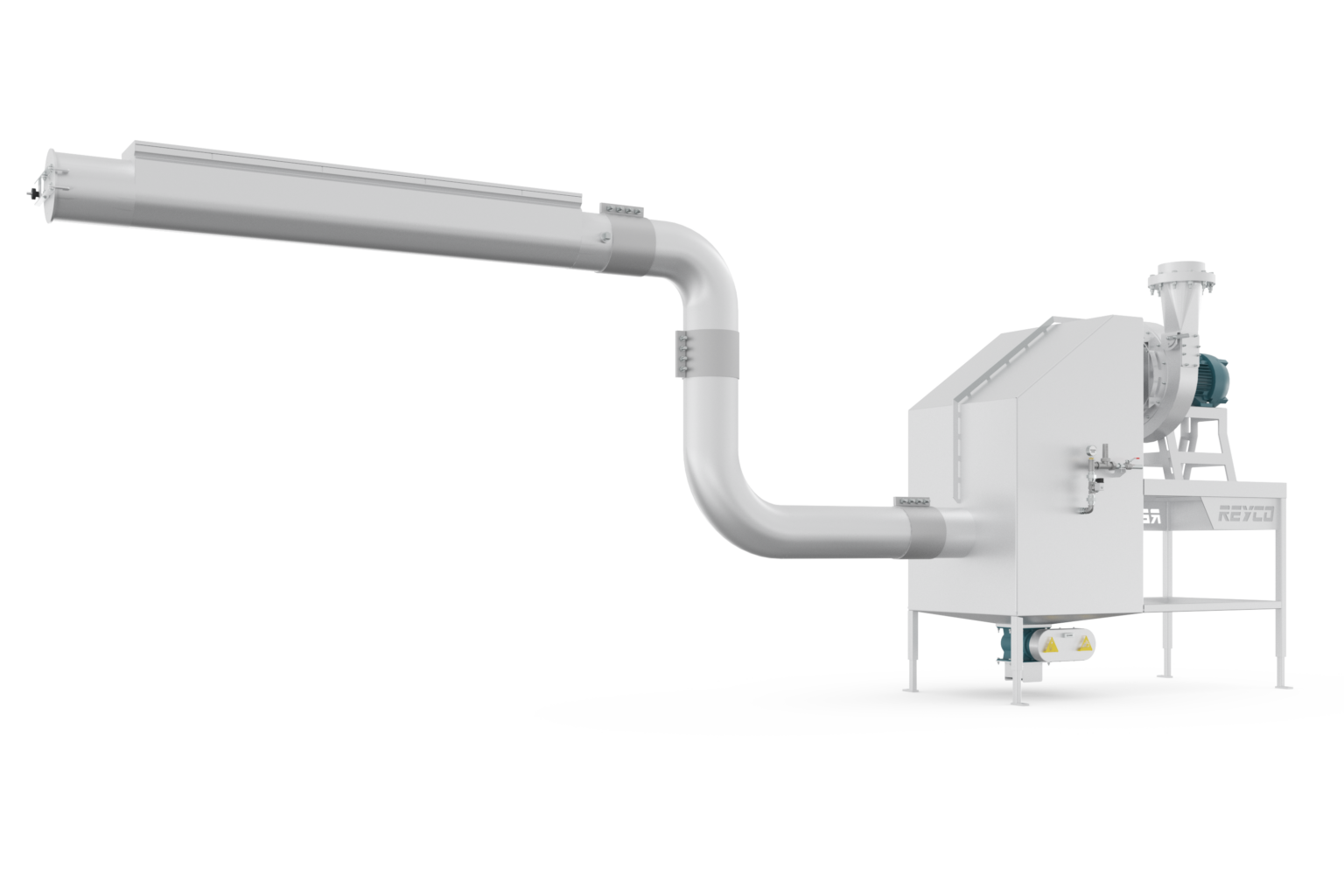

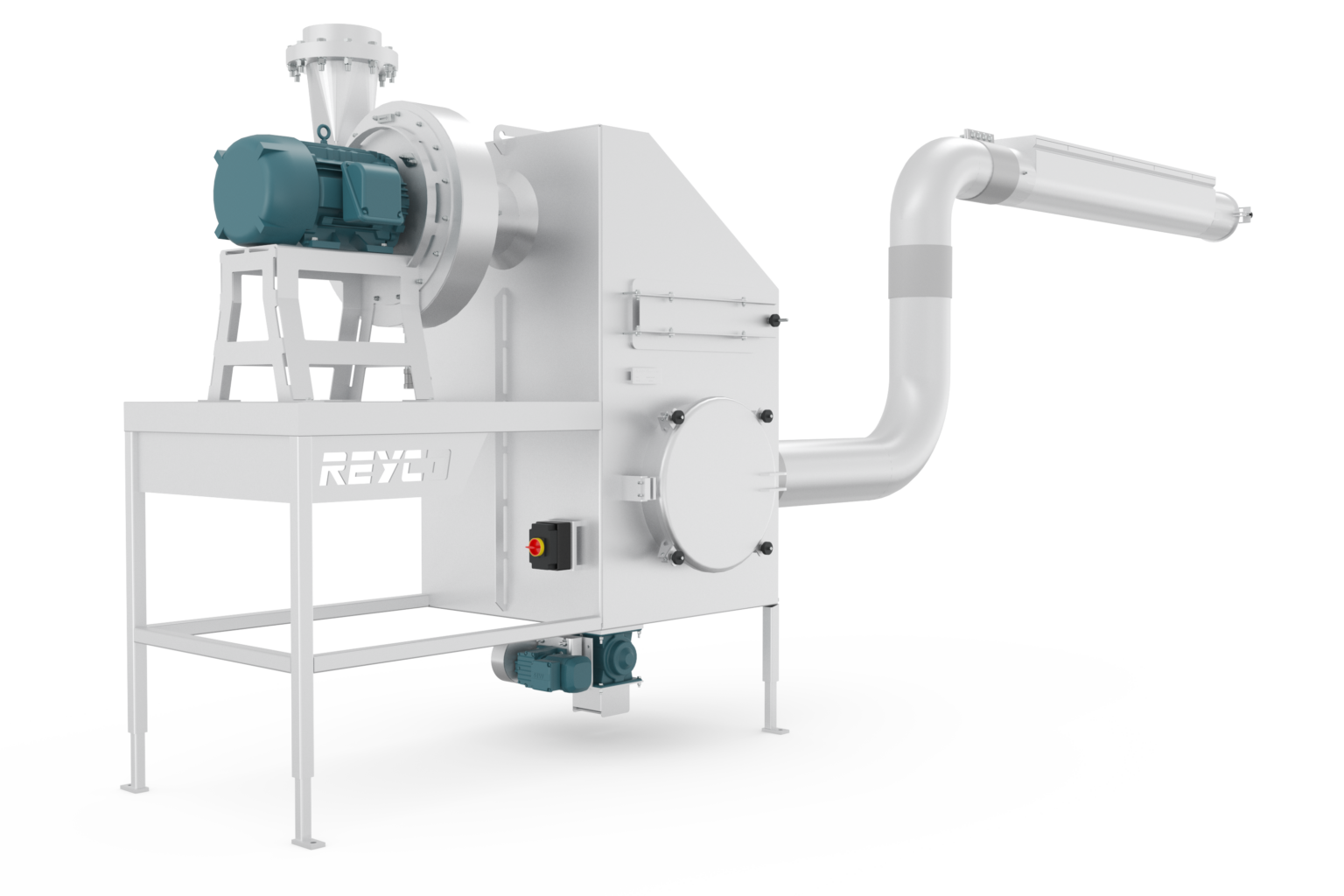

The WaterVac System includes a blower that creates a vacuum beneath a mesh belt, available in sizes from 10 to 30 HP, with customizable suction plenums to suit various conveyor types. A conveyor can also be custom-built if needed.

Partner with REYCO Systems, the industry leader in precision-engineered food processing solutions. Our cutting-edge technology enhances efficiency, reliability, and safety, helping food processors worldwide achieve peak performance. Contact us today to discuss how our innovative systems can elevate your operations.

Phone: (208) 795-5700

Fax: (208) 795-5749

Email: reycosales@reycosys.com

Address: 1704 Industrial Way Caldwell, ID 83605

© 2005 REYCO Systems, Inc. and/or its suppliers, 1704 Industrial Way, P.O. Box 460, Caldwell ID 83606-0460 U.S.A. All rights reserved. Any rights not expressly granted herein are reserved. WaterVac, EcoVac, EcoMiser, DynaMiser, VentPac, GasPac, and CoolPac are either registered trademarks or trademarks of REYCO Systems, Inc. in the United States and/or other countries. The names of actual companies and products mentioned herein may be trademarks of their respective owners. This Web site is intended for informational purposes only. REYCO Systems, Inc. makes no warranties, express or implied, as to the information in this Web site. Contact REYCO Systems, Inc. with questions or problems with this service.

© REYCO Systems 2025 | PO Terms and Conditions