Air Make-Up Units (AMUs) are critical in maintaining air quality, temperature regulation, and overall efficiency in industrial and food processing environments. However, like any essential equipment, AMUs require regular maintenance to ensure optimal performance, safety, and longevity. Neglecting routine care can lead to costly downtime, energy inefficiencies, and significant safety hazards.

Why Regular AMU Maintenance Matters

Over time, dust, grease, and airborne debris accumulate in an AMU, restricting airflow and reducing efficiency. If left unchecked, this buildup can obstruct electrical components and air vents, leading to overheating and potential system failures. In extreme cases, the risk of fire increases, endangering both personnel and property.

Routine inspections and preventative maintenance not only extend the lifespan of your equipment but also help you avoid unexpected breakdowns, ensuring a safer and more cost-effective operation.

Key Benefits of AMU Maintenance

- Improved Efficiency

A well-maintained AMU operates at peak efficiency, reducing energy consumption and lowering utility costs. Clean filters, unobstructed airways, and properly functioning components allow the unit to distribute air effectively, optimizing environmental conditions. - Extended Equipment Lifespan

Regular servicing can significantly prolong the life of an AMU, delaying the need for costly replacements. When filters, motors, and electrical systems are cleaned and inspected routinely, they perform better and last longer. - Enhanced Safety & Compliance

Keeping up with scheduled maintenance helps facilities remain compliant with safety regulations. By preventing excessive buildup and monitoring system conditions, businesses can reduce the risk of fires and malfunctions that may result in workplace hazards.

Common Maintenance Challenges and How to Address Them

- Clogged or Damaged Filters

Accumulated dirt and debris reduce airflow and force the system to work harder, increasing wear and tear. Regular filter checks and replacements are essential for maintaining efficiency. - Overheating Motors and Electrical Components

Blocked air passages and dust-covered electrical parts can cause overheating and system failure. Keeping these areas clean ensures safe operation. - Wear and Tear on Moving Parts

Mechanical components, such as fans and belts, degrade over time. Regular inspections help identify worn parts before they fail, preventing unexpected shutdowns.

Steps to Maintain Your AMU Effectively

To ensure your AMU continues to perform reliably, follow these key maintenance practices:

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule to prevent debris buildup and mechanical issues.

- Inspect Filters Regularly: Keep filters clean and replace them as needed to maintain proper airflow.

- Monitor for Unusual Signs: Uncommon noises, overheating, or reduced efficiency could indicate a problem requiring immediate attention.

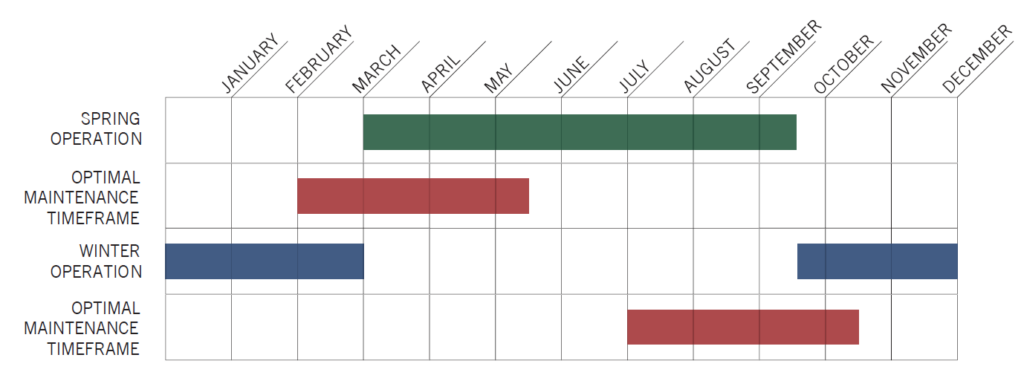

- Schedule Professional Inspections: Annual maintenance checks by qualified technicians can identify hidden issues before they lead to costly repairs.

Additional Ways to Optimize Your AMU

Beyond standard maintenance, upgrading your AMU with modern safety and performance enhancements can provide additional benefits:

- Sensing Devices: Adding temperature sensors and smoke detectors can help monitor system performance in real-time, allowing for early intervention.

- UV Grid Installation: A UV grid can eliminate airborne bacteria, mold, and viruses, improving air quality and food safety.

- Service Contracts: Partnering with a maintenance provider for semi-annual inspections and tune-ups ensures your AMU remains in top condition year-round.

Protect Your Investment with Proactive Maintenance

By implementing a routine maintenance plan, businesses can safeguard their AMUs against premature failure, ensure a safer working environment, and maximize efficiency. Taking proactive steps today will help avoid costly repairs and downtime in the future.

Contact REYCO Systems for more information on optimizing your AMU’s performance or to schedule a professional inspection. Proactive maintenance isn’t just the best practice, it’s an investment in long-term reliability and safety.